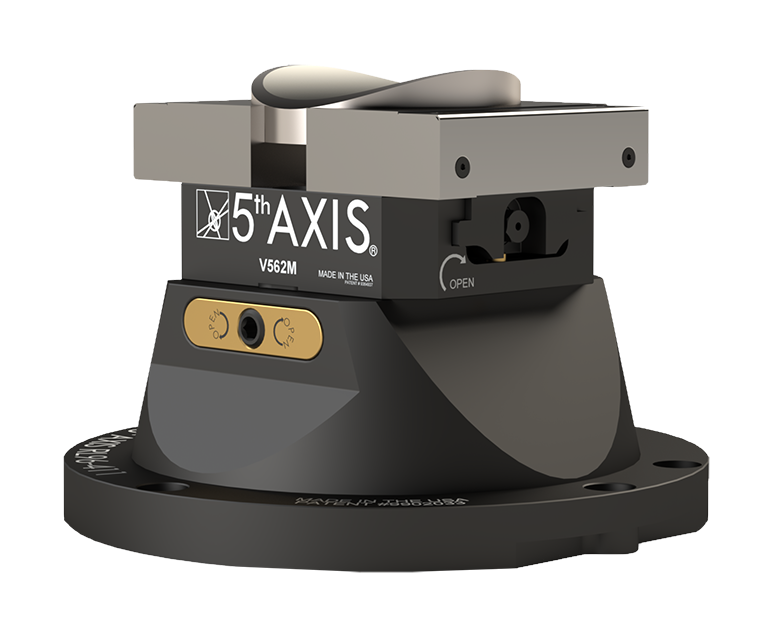

TRUE SELF-CENTERING

Find A Vise

Jaws Close On Center

The Left- and Right- handed leadscrew positions your workpiece in the center of the vise with exceptional accuracy. Centering Repeatability of 12.7 µ (.0005″)

Low Profile, Small Footprint

Full access to the workpiece is the name of the game. Easily reach five sides of the workpiece.

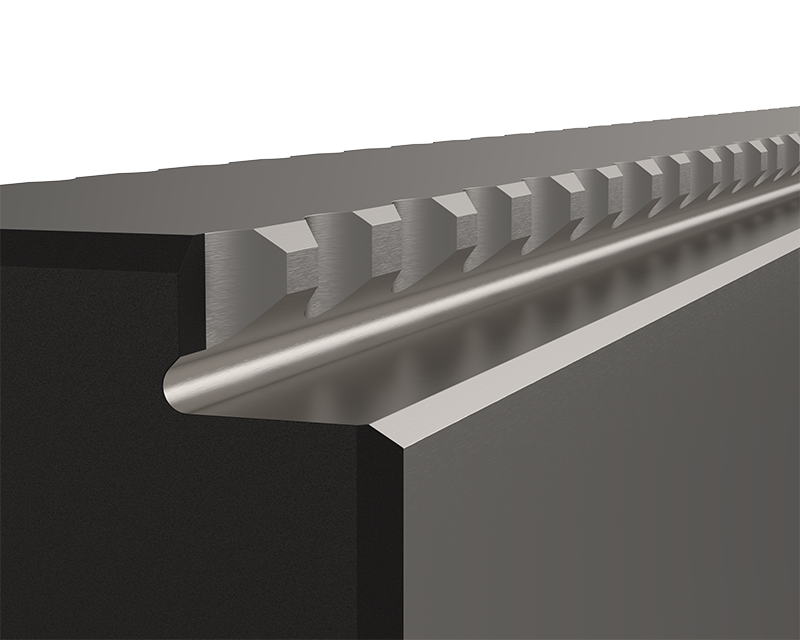

Gripper Teeth + Dovetail.

Serrated teeth on each jaw provides maximum grip on stock less than HRC 35. For harder material, the built-in dovetail provides exceptional clamping force without the need for a stamping machine and with even less torque.

Clamping Force at Max Torque 22.2 kN (5000 lbf) – V75100X

Clamping Force at Max Torque 22.2 kN (5000 lbf) – V75100X

Simple Design.

Quickly reverse jaws / change jaws on the fly. Our simple bolt on jaw design eliminates the need to take apart the vise to change jaws.

Built Tough.

All 5th Axis vises are built in the USA from hardened American steel. Vise bases are 32 HRC + vise jaws are 55 HRC. With the serrated teeth or the dovetail you can grip nearly any stock type.

Made For Soft Jaws.

Quickly remove the standard hard jaws and replace them with machinable jaws. Soft jaws are used for secondary operations + finishing work.

RockLock / Direct-Mount Ready.

Utilzing the RockLock quick change system or another 52mm / 96mm pull stud quick change system? Simply thread in the pull studs and the vise is now ready for quick change.

Direct mount all 5th Axis vise from the top down utilizing standard socket head cap screws. Bolt the vise directly to the t-slots on the machine table.

Direct mount all 5th Axis vise from the top down utilizing standard socket head cap screws. Bolt the vise directly to the t-slots on the machine table.